AMORPHOUS ALLOY METAL

Amorphous Energy efficient Distribution Transformer

In recent years, energy savings is an urgent issue as a countermeasure against global warming.

The future of the power industry will be shaped by a range of disruptive themes. Distribution transformers are used for the distribution of electric power.

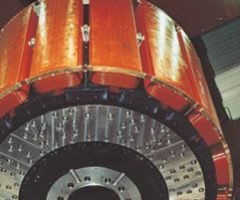

One of the key components of electric transformers is its central Core which is made of Cold Rolled Grain Oriented Electrical Steel (CRGO Electrical Steel), CRGO core have been used in transformers for over 75 years.

AMORPHOUS METAL

Power industry today is searching for a technology that saves energy and reduces their operating costs. To meet this demand our partners have developed Amorphous alloy metal core material optimised for Power industry, specifically for use in distribution transformers.

Amorphous metal is an alloy with a non-crystalline structure produced by ultra-rapid quenching.

To produce amorphous metal, melted alloy is rapidly cooled at a speed of About 1 million centigrade per second. Amorphous metal does not have a crystalline structure, it has a random atomic structure which makes it extremely efficient in transformer applications. It also has excellent magnetic properties such as high permeability and low loss while having a high-saturation magnetic flux density.

Distribution transformers made of amorphous alloy save significant amount of energy and cost. Amorphous transformers are already in use in many countries including Japan, USA, Europe Union, China, and India.

Amorphous material can be reused and recycled.

Energy Efficiency

Energy loss of transformers largely depends on the magnetic properties of the material used for the construction of the core. Amorphous alloy reduces core loss by up to 70%. No-load loss (stand-by loss) of amorphous transformer is reduced by 1/3 compared to CRGO Conventional transformer. Amorphous transformer also reduces CO2 emissions by saving energy since less energy is generated and losses are lower in the distribution system. Amorphous alloy is a material that saves energy and contributes to the environment.

Cost Efficiency

Most distribution transformers can operate for 20 to 30 years. When purchasing a transformer, one must consider operating costs along with the initial purchase price. Today the initial purchase price of amorphous distribution transformers (AMDT) is about the same as CRGO Conventional distribution transformer, this wasn’t the case in the past as AMDT were much more expensive, the long-term operating costs of AMDT are substantially lower than the conventional distribution transformers.

The Total Owning Cost (TOC) is calculated based on the Initial Price plus Cost of Running it over its useful life 20-30 years.

Purchasing decisions requires the right balance between purchase cost and the cost of future losses.

Various other applications of Amorphous Alloy Metal in Power Sector

Besides Transformers, Amorphous alloy metal is used in Inverters (Solar Inverters and Wind Inverters)

Switch-Mode Power Supply etc. amorphous alloy provides ideal solution in the power industries, allowing us to save energy, helping us to reduce fossil-fuel dependency and to create cleaner environment with higher air quality.

Technical Analysis

Amorphous alloy metal applications

Distribution transformer (DT) for Power Grid

More than ever, electric utilities and industries today are searching for technologies that will reduce their operating costs and improve energy savings throughout their distribution systems.

New Transmission and Distribution (T&D) technologies are now available to help utilities meet these goals.

With new generation of Amorphous metal distribution transformers (AMDTs) – with up to 70% lower core loss then Conventional Transformers, AMDTs are helping utilities companies worldwide to achieve their efficiency objectives. When you consider that 10% of all electricity generated by utility companies is lost in the transmission and distribution process, the potential for savings through reductions in core loss can be significant.

Amorphous Core for Solar Inverter and Wind Inverter

Competitive Advantage

Energy saving and CO2 emission reduction because of low losses

No Load Loss (Stand-by-Loss) of Amorphous Transformer is 1/3 of that of CRGO Transformer. Stand-by-Losses are significant in electricity distribution

Total Owning Cost of Distribution Transformer (DT)

DT usually can operate 20-30 years or more (average life in EU is around 40 years) TOC takes account of initial price and running cost in a lifetime. Running cost of AMDT is lower than the CRGO transformers.

Competing products

CRGO, this is traditional steel and comes in many grades.The Amorphous Transformer’s No-Load-Loss is much lower then that of the best grade CRGO transformer.